Industry Dynamic

What factors will affect the reliability and durability of auto electrical connectors

Mar 07,2024

Auto electrical connectors are essential components in modern vehicles as they facilitate the transfer of electrical signals between different parts of the vehicle. The reliability and durability of these connectors play a crucial role in ensuring the overall performance and safety of the vehicle. There are several factors that can affect the reliability and durability of auto electrical connectors, and in this essay, we will discuss some of the main factors.

1. Material Quality

The primary factor that affects the reliability and durability of auto electrical connectors is the material quality. These connectors are usually made of metals, such as brass, copper, and aluminum, and the quality of these materials determines their resilience to wear and tear. Cheap or low-quality materials are more susceptible to corrosion, which can lead to poor contact and malfunction of the connectors.

2. Environmental Factors

Auto electrical connectors are often exposed to various environmental conditions, such as high temperatures, moisture, dust, and chemicals, which can affect their reliability and durability. High temperatures can cause the connectors to melt or deform, while moisture and dust can cause corrosion and damage to the connectors. Chemicals can also corrode the connectors and affect their performance.

3. Proper Installation

The way auto electrical connectors are installed also plays a significant role in their reliability and durability. If the connectors are not properly installed, they may experience loose connections or may be prone to damage due to vibrations. It is essential to follow the manufacturer's guidelines and use the correct tools and techniques to ensure the connectors are installed correctly.

4. Overloading and Vibration

Another factor that can affect the reliability and durability of auto electrical connectors is overloading and vibration. When the connector is overloaded, it may overheat and fail, while excessive vibrations can cause the connectors to loosen, leading to poor contact and potential failure. It is crucial to ensure that the connectors are not overloaded and are securely fastened to prevent vibrations from affecting their performance.

5. Maintenance

Regular maintenance is crucial to ensuring the reliability and durability of auto electrical connectors. Over time, these connectors may develop loose connections or corrosion, which can lead to malfunctions. Regular cleaning and inspection can help identify any potential issues and address them before they cause significant problems.

6. Design and Manufacturing

The design and manufacturing process of auto electrical connectors can also affect their reliability and durability. Connectors with poor design or subpar manufacturing processes may have weak points or flaws that make them more susceptible to damage or malfunction. It is crucial to choose connectors from reputable manufacturers that use high-quality materials and have a track record of producing reliable and durable products.

What are automotive electrical connectors?

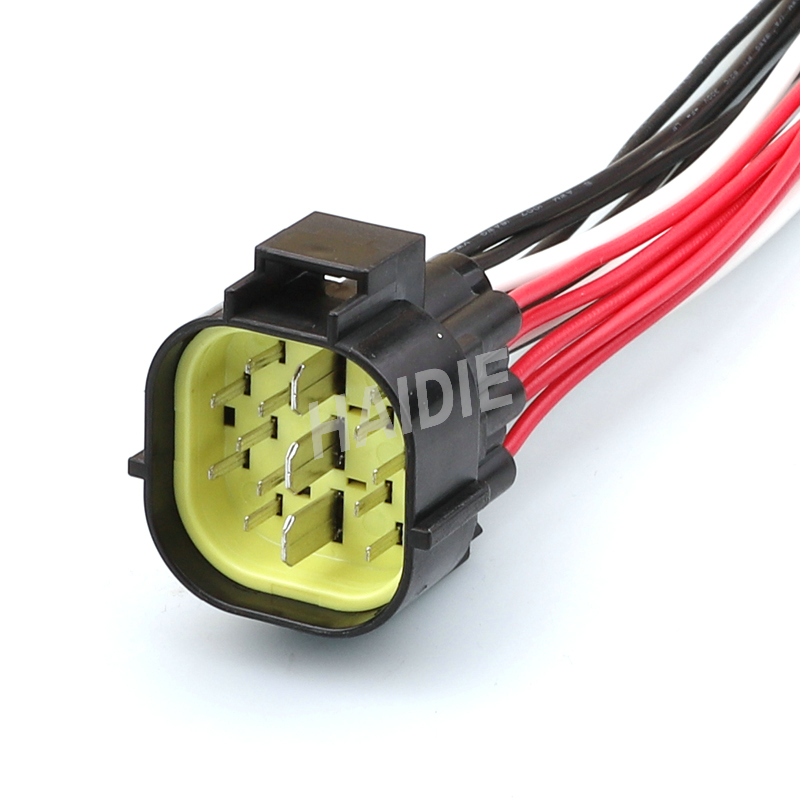

Automotive electrical connectors are devices used to connect electrical wires and components in a vehicle's electrical system. These connectors have various sizes and shapes and are designed to facilitate a secure and reliable connection between electrical components, such as sensors, switches, lights, motors, and the vehicle's main wiring harness. They can be made of plastic, rubber, or metal and often have different color coding to help with the identification of the wires they connect.

These connectors are essential in modern vehicles, as they allow for easy installation, maintenance, and repairs of the vehicle's electrical system. Without these connectors, the electrical system in a vehicle would be a mass of tangled wires, making it difficult to troubleshoot and repair any issues.

What are the failure modes of connectors?

1. Physical Damage/Corrosion: Connectors can become damaged due to rough handling, excessive use or exposure to harsh environments. Physical damage can cause the contacts to become deformed, lose their grip, or even break off completely. Corrosion of connectors can also occur in humid and corrosive environments, leading to poor electrical connections and failure.

2. Misalignment: If not connected properly, connectors may become misaligned. This can cause damage to the contacts and lead to poor electrical connections. Misalignment can also occur if the connector is not mated correctly, resulting in a loss of signal or power.

3. Insulation Failure: The insulation of a connector can fail due to age, heat, or exposure to chemicals. This can result in short circuits, cross-talk, or other electrical interference.

4. Electrical Overload: Connectors that are not designed to handle high voltage or current can fail when overloaded, resulting in damage to the contacts or insulation, or even fires.

5. Contamination: Dust, dirt, moisture, and other debris can enter the connector and cause corrosion, block connections, and lead to failures.

6. Vibration: Connectors that are not securely attached or have loose contacts can experience frequent vibrations, which can cause the contacts to loosen and result in a loss of signal or power.

7. Incompatibility: Using incompatible connectors can result in poor connections, damage to the contacts, or electrical interference.

8. EMI/RFI Interference: Electromagnetic interference (EMI) or radio frequency interference (RFI) can cause connectors to malfunction and fail, resulting in a loss of signal or power.

9. Bend Radius and Wear: Connectors that are subjected to frequent bending, twisting, or pulling can experience wear and tear, resulting in damage to the contacts and eventual failure.

10. Manufacturing Defects: Poorly manufactured connectors can have defects that can cause failures, such as improper mating, loose contacts, or weak insulation.

YUEQING HAIDIE ELECTRIC CO.,LTD

Is located in Wenzhou Yueqing which is the beauty of the East China Sea. Our company is 2 kilometers away from the Wenzhou Airport and 20 kilometers away from the Wenzhou Railway Station. The traffic is very convenient. Our company is specialized in the production of automotive electrical and automotive parts.

Our products include wire harness, connectors,auto connectors, automotive plug sockets, computer board fittings, terminals, high temperature anti-corrosion silicone rubber jackets, HID lights, and electrical instruments.

Our products are widely used in automobile motorcycle, engineering machinery, engine control systems, household appliances, computers, communications and digital products.

We have a strong ability to develop new products and follow the development of mold. Our cooperative corporations are FAW Group, FAW-Volkswagen, Shanghai Volkswagen, Chery Automobile, Chang'an Group, Chang'an Ford, General Motors, SUZUKI, Hafei, Nissan etc.

Our products are exported to Japan, South Korea, South-east Asia, the United States and other western European countries.

Recent news

Exploring the Versatility of Auto Connectors: A Comprehensive guide by Haidie

What is auto connector?Auto connector is a component used in vehicles to join electrical circuits. These connectors are ···

What is auto connector and how to produce it?

What is auto connector?Auto connectors, also known as automotive connectors, are devices used in the automotive industry···

Why you should choose auto connector?

Auto connectors are essential components in the automotive industry, enabling effective communication between different ···